Measurement

EXCELLENCE IN MEASUREMENT TECHNOLOGY THROUGH DIGILAB AND I4.0 TECHNOLOGY

By utilizing a comprehensive selection of cutting-edge quality laboratory and measurement technologies, we ensure that our customers always benefit from top-notch performance. Our digitalized quality labs employ innovative I4.0 technologies to enable more efficient testing procedures, automated evaluations, advanced visualizations, and enhanced productivity. Thus, we not only optimize our production processes but also provide our customers with service of the highest level.

PRECISION MEASUREMENT TECHNOLOGY WITH TACTILE MEASUREMENT SYSTEMS

Precision Measurement with 3D Coordinate Measuring Technology

Our state-of-the-art tactile measurement systems set new standards in measurement technology. With 3D coordinate measurement technology, we guarantee maximum precision in measuring your components and tools. Thanks to modern 3D coordinate measuring machines, we can measure components with dimensions up to 4,000 x 1,500 x 1,200 mm and ensure that the required tolerances are precisely met. Tactile measurement technology allows for reliable measurement of complex geometries and hard-to-reach areas. Trust in our expertise in measurement technology and benefit from the highest measurement accuracy and process reliability.

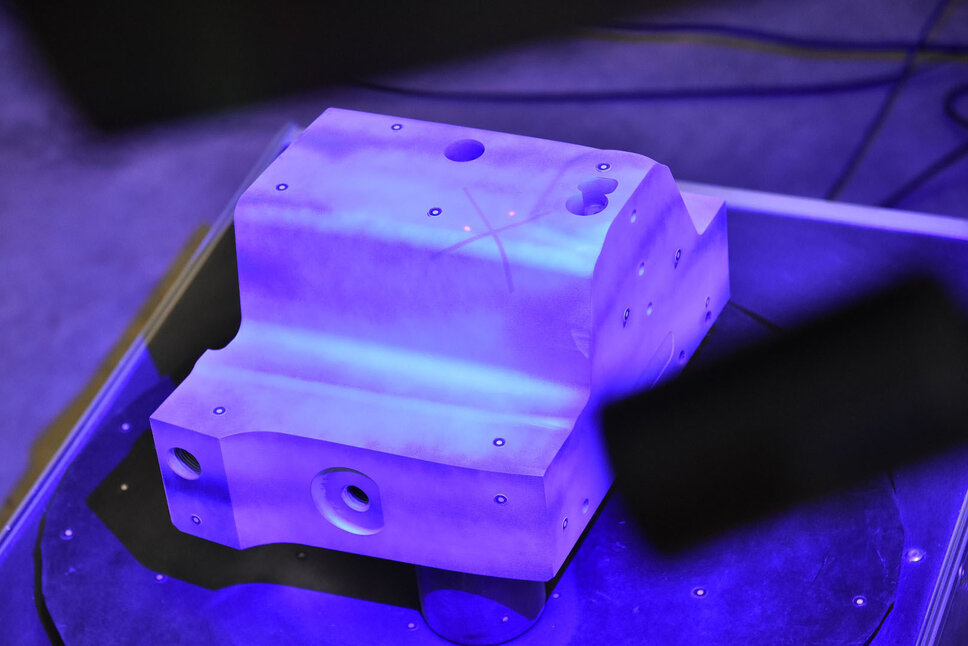

DIGITAL MEASUREMENT WITH STATE-OF-THE-ART MEASUREMENT TECHNOLOGY

Precision and Speed in Real-Time through 3D Scanning Technology

With our advanced 3D scanning technology, we set new standards in digital measurement. Utilizing powerful 3D scanners and highly developed sensor technology, we provide precise real-time measurements for your components and tools. This technology not only ensures the highest precision but also enables fast and efficient measurement processes—ideal for complex geometries and detailed analyses. Rely on our digital measurement solution to reliably meet your quality requirements and optimize processes.

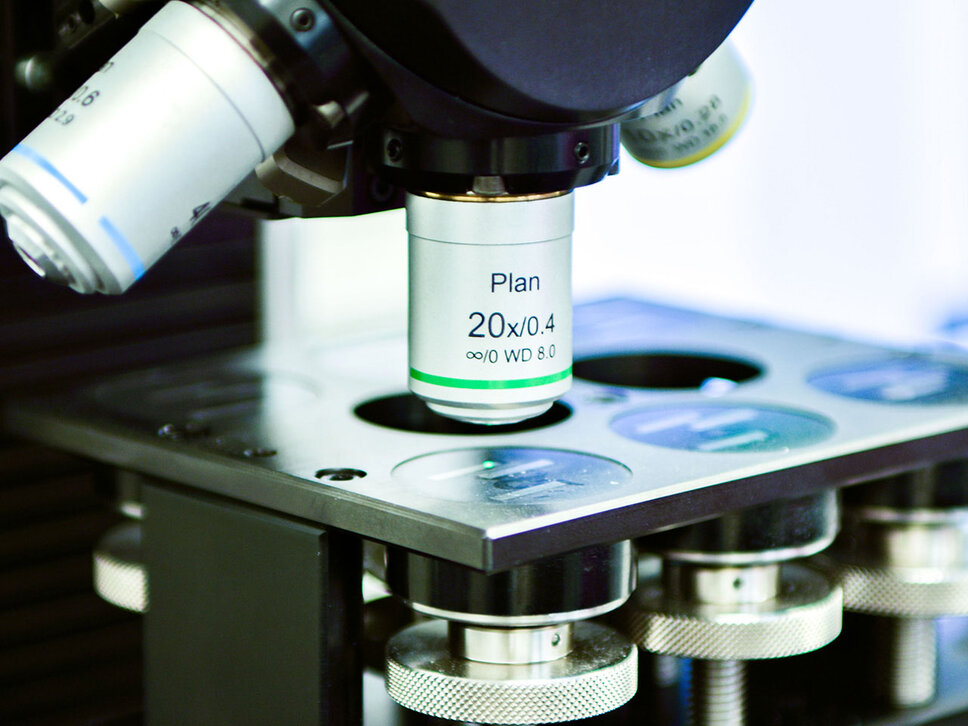

METALLOGRAPHIC ANALYSES AND MECHANICAL MATERIAL TESTING IN MEASUREMENT TECHNOLOGY

Comprehensive Testing of Material Properties

Our comprehensive metallographic analyses and mechanical material tests set standards in measurement technology. Using microscopic examinations, we analyze the structure and properties of metals and alloys down to the smallest detail. Additionally, we conduct tensile, bending strength, and hardness tests to ensure the quality and durability of your products. With state-of-the-art testing methods and the highest precision, we ensure that every component meets our high standards and fulfills customer requirements. Trust in our expertise in measurement technology for reliable results.

Quality Assurance through Modern Measurement Technology

Contact us today to learn more about our services in measurement technology.

Certified Quality in Measurement Technology

Our company is certified according to both ISO 9001:2015 and IATF 16949. These certifications demonstrate our commitment to the highest quality standards and process efficiency, meeting industry-leading requirements.

ISO 9001:2015 - The Standard for Quality Assurance

With the ISO 9001:2015 certification, we affirm our commitment to providing high-quality products and services. This certification confirms that our internal processes meet the highest international standards and that we are continuously working to improve our workflows.

IATF 16949 - Excellence in the Automotive Industry

The IATF 16949 certification highlights our capability to meet the demanding and specific requirements of the automotive industry. It shows that we not only meet the highest quality standards but also live them in our daily work.

Efficiency Boost through AI: How Our New Digital Quality Lab Takes Quality Assurance to the Next Level!

Learn in our news article how the use of advanced AI in our new digital quality lab is revolutionizing efficiency and precision in quality assurance. A milestone for Industry 4.0!