Contents: Differences and Applications in Hot Forming

- Process Flow in Hot Forming

- Heating Sequence in Hot Forming

- Forming Step in Hot Forming

- Forming Limits and Component Distoration in Hot Forming

Process Flow in Hot Forming

Direct Hot Forming: In direct hot forming, the preformed blank is heated directly to the austenitizing temperature before being placed into the forming tool.

Indirect Hot Forming: In contrast, indirect hot forming involves cold deep drawing the component initially to obtain a preform. This preform is then heated to the austenitizing temperature and inserted into the hot forming tool to achieve the final shape.

Heating Sequence in Hot Forming

Direct Hot Forming: In direct hot forming, the blank is heated to the austenitizing temperature in a furnace, such as a continuous furnace. Continuous heating of the blanks allows for efficient production but requires careful control of temperature and dwell time in the furnace.

Indirect Hot Forming: In indirect hot forming, the preform is heated to the austenitizing temperature after cold deep drawing. Heating also occurs in a furnace.

Forming Step in Hot Forming

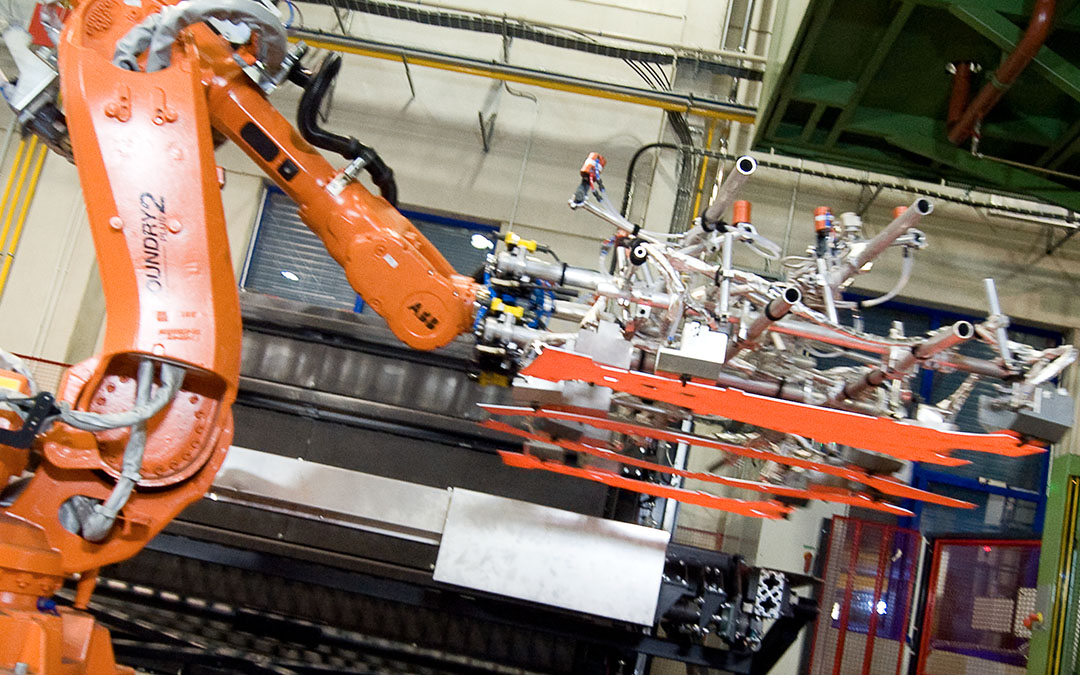

Direct Hot Forming: In direct hot forming, the heated blank is quickly placed into the forming tool and shaped. The heat in the material is utilized optimally, and the blank is then rapidly cooled to ensure sufficient quenching.

Indirect Hot Forming: In indirect hot forming, the heated preform is inserted into the hot forming tool and drawn into the final shape. Subsequent cooling for quenching also takes place.

Forming Limits and Component Distortion in Hot Forming

Indirect Hot Forming: The additional preforming step in indirect hot forming allows for the manufacture of more complex geometries with less component distortion. This expands the forming limits and enables the production of sophisticated components.