The success story of webaWerkzeugbau began modestly in 1982 as a small tool and mold manufacturing company in Dietach, Austria, specializing in the production of forging dies, molds, and machining solutions for regional businesses. In 1987, a decisive moment occurred when weba entered the automotive industry for the first time. Since then, the company has increasingly focused on the production of stamping tools for vehicle components. Success followed suit, leading weba to expand its production capacity into the Czech Republic. In this process, additional expertise in forming technology and tool manufacturing was developed. In 1994, the company successfully designed and produced its first hot forming tool, also called press hardening tool. With the growing complexity of production and an expanding workforce, the demands for quality assurance and process management also increased.

To ensure consistently high quality of tools and products across both locations, processes were increasingly standardized. In 1995, weba obtained successful certification according to the internationally recognized ISO 9001 standard for quality management systems. Customer satisfaction, compliance with legal requirements, and continuous improvement of quality and processes have since been central concerns of the company's management.

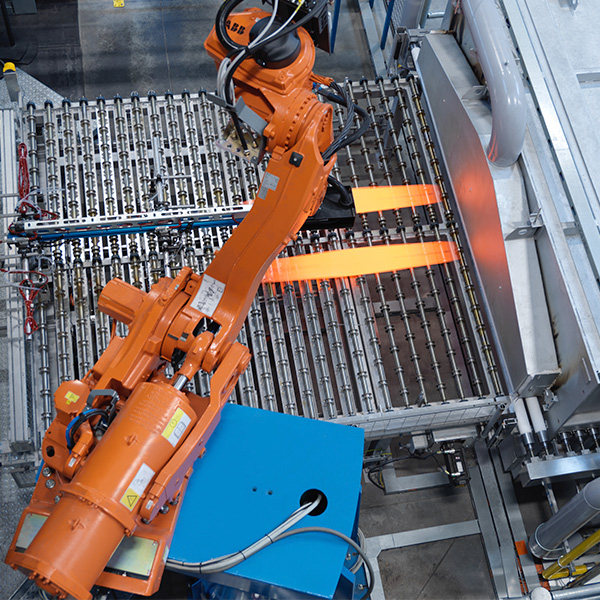

In 2018, weba acquired a fully automated hot forming system with roller hearth furnaces and initiated preparations for certification according to the IATF 16949 standard. This standard builds upon ISO 9001 and specifies particular requirements for quality management systems in the serial and spare parts production within the automotive industry. One year of intensive preparation followed, during which weba's hot forming team worked diligently to adapt processes, production, and documentation to meet serial production requirements. The logistics concept was optimized, and new systems and methods for traceability were introduced. Additional quality assurance measures were implemented.

Certification according to the IATF 16949 standard requires a demonstrated commitment to consistent implementation and practice within the organization for at least one year. In 2021, weba successfully completed the certification process. Robert Raich, Operations Manager at the Olomouc site, emphasized, "With the IATF 16949 certification, weba has achieved another significant milestone as a reliable supplier to the automotive industry." The company is now capable of supplying and supporting its customers with small series, start-up production, and in the event of press failures for press hardening in accordance with serial production standards.

The IATF 16949 certification underscores weba's commitment to meeting and continuously improving the highest quality standards. The company continues to focus on innovation, cutting-edge technology, and highly qualified personnel to meet the increasing demands of the automotive industry. By fulfilling the IATF 16949 standard, weba is establishing itself as a trusted partner for automotive manufacturers and consistently pursuing its path of success.

-----

About weba Werkzeugbau: weba is a leading provider of high-quality stamping and forming tools for the automotive industry. With its headquarters in Dietach, Austria, the company has extensive experience in the development and manufacturing of tools for vehicle production. weba stands for the highest quality, innovation, and customer satisfaction.